THE SOLUTION

Tyrecrete replaces elements of the aggregates in concrete with minimally processed end-of-life tyres.

There were 22.163 million tonnes of ready mixed concrete produced in the UK last year, this equates to 9.23 million m³ with over 14 million tonnes of aggregates used. We are extremely confident that with mobile and static plants readily available across the UK and an incentivized lower cost drop off for end-of-life tyres, we can end the blight of fly tipped tyres across our fragile countryside. Using shredded tyres at just 5% mix replacement in just 20% of the annual volume could remove the necessity to send 12 million tyres abroad.

This innovative concrete material not only enhances the flexural strength of the final product, the technology contributes to reducing landfill waste, mitigating greenhouse gas emissions and decreasing demand for stone aggregates. Furthermore, this technology proves highly effective in filling voids or stabilising structures prone to movement, such as mine shafts, sewers, or building foundations. It’s natural resilience and ability to bond effectively with cement offer long-lasting properties, making the material a sustainable choice for construction applications.

Helping Manufacturers to acheive net zero and reduce production costs with the TyreCrete process:

End-of-Life Tyre

Shredder Plant

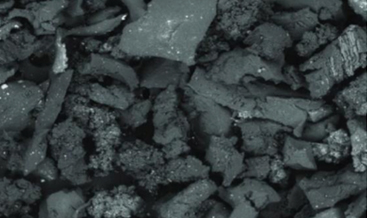

Shredded Tyre

Promoting the Circular Economy

Contact Tyrecrete today...

A solid environmental solution to end-of-life tyres.